However, this approach comes with significant costs for purchasing and maintaining that inventory. Going forward, manufacturers will likely need to find a balance between JIT and JIC manufacturing to effectively control overhead, while minimizing supply chain risks. The JIT methodology requires that manufacturers establish strong relationships with suppliers and supply chain visibility to ensure that materials are delivered reliably and without interruption. Manufacturers must also implement standardized internal processes, with an emphasis on efficiency and effective communications. In addition, they must continuously look for ways to improve business processes and operations, no matter how well they currently work.

Quality Control:

Any disruptions in the supply chain can have a ripple effect, impacting production schedules and customer satisfaction. JIT manufacturers strive to eliminate all forms of waste in the manufacturing process, including waste of materials, labor, and time. Despite these risks, JIT can be a very effective inventory management method for companies that are able to manage their inventory levels effectively. JIT can help companies reduce their costs, improve their cash flow, and free up space in their warehouses. One potential risk lies in the “bullwhip effect”, which refers to the tendency for small fluctuations in demand to amplify as they move upstream in the supply chain. The JIT inventory system is popular with small businesses and major corporations because it provides more efficient use of working capital and enhances cash flow.

Free Lean Six Sigma Templates

The JIT system can be especially helpful to small businesses that are just starting out. It can reduce the amount of capital required to get the business up and running. Obviously, using this sort of inventory method works only if a company has an efficient inventory management system and reliable suppliers.

Pros and Cons of JIT Inventory Management

Our writing and editorial staff are a team of experts holding advanced financial designations and have written for most major financial media publications. Our work has been directly cited by organizations including Entrepreneur, Business Insider, Investopedia, Forbes, CNBC, and many others. For information pertaining to the registration status of 11 Financial, please contact the state securities regulators for those states in which 11 Financial maintains a registration filing. A just-in-time system needs to be carefully tracked and organized, which will be hard if you are doing it manually.

This requires a high level of trust and cooperation between the manufacturer and its suppliers. JIT manufacturers also typically use electronic data interchange (EDI) systems to automate the ordering and receiving of goods. consignment sale definition EDI systems help to ensure that orders are accurate and that goods are delivered on time. The producing company may face a significant problem if, for example, the delivery of raw materials is delayed for some reason.

- JIT inventory management requires high-quality inputs to avoid production disruptions and customer dissatisfaction.

- The inventory turnover ratio is a metric used in corporate finance to estimate how efficiently a company is selling its products.

- Therefore, just in time saves you a lot of costs which would otherwise be tied up as inventory holding cost.

- Companies utilize the Just in Time method of inventory accounting so that it directly aligns with the goods they are producing.

We don’t guarantee that our suggestions will work best for each individual or business, so consider your unique needs when choosing products and services. Since you have to replenish stock as soon as you sell it, you don’t have the luxury of waiting around for the best price. So if your supplier charges extra for your order due to a recent natural disaster or national holiday, it’ll eat into your bottom line.

JIT inventory management reduces inventory levels to minimize costs, which can increase the risk of stockouts if demand is higher than expected. The Just-in-Time (JIT) inventory management system is a method of keeping inventory levels as low as possible by receiving goods only as they are needed for production or sale. This contrasts with traditional inventory management methods, which involve keeping a stockpile of inventory in order to meet anticipated demand.

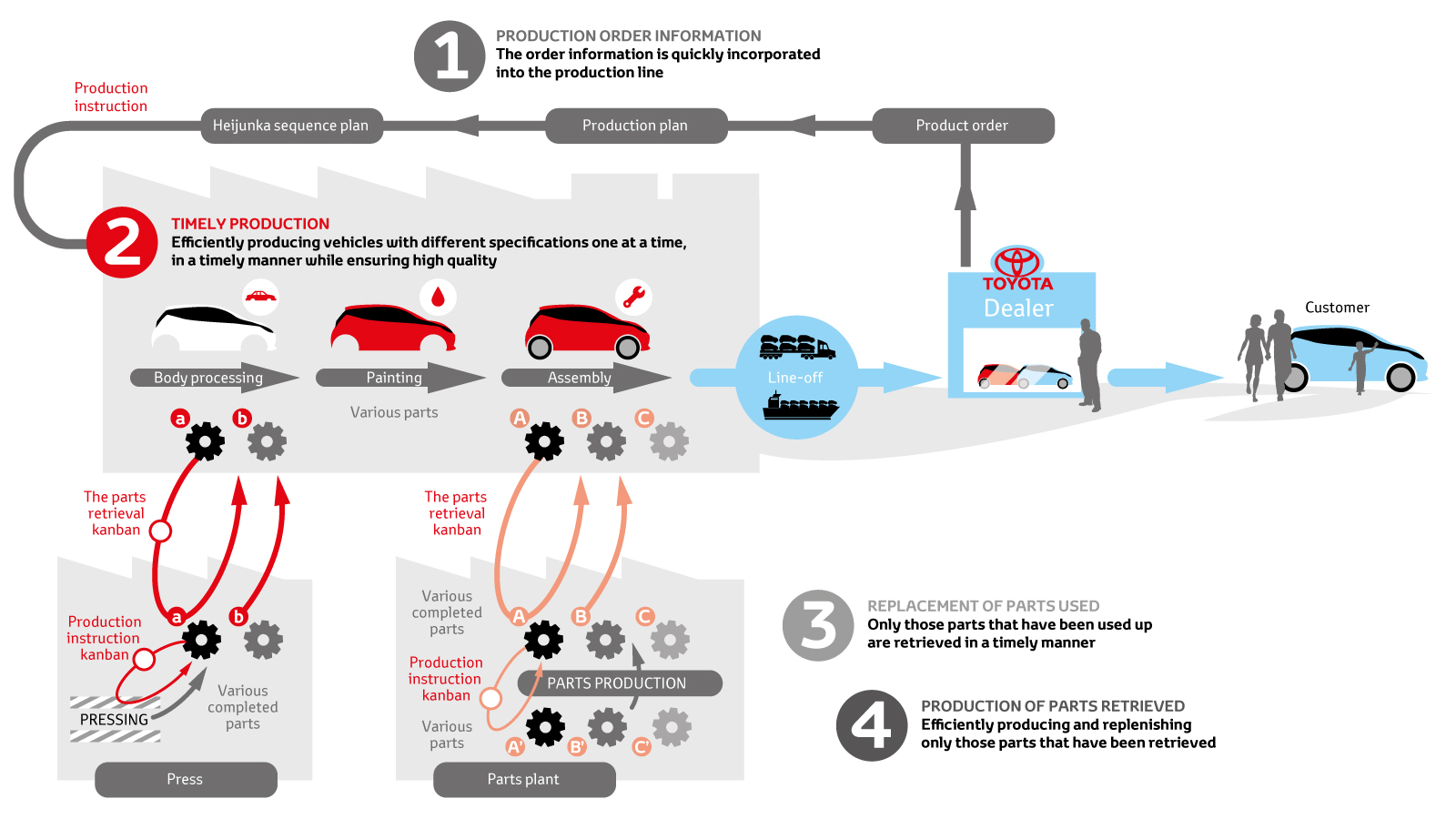

Decreased inventory means a smaller denominator in both these formulas, leading to healthier ratios across the board. And, of course, the JIT inventory system can be found in automobile manufacturing, where it was first developed by Toyota Motor Corporation (TM). Executives reasoned that the company could adapt more quickly and efficiently to changes in trends or demands for model changes if it did not keep any more inventory in-store than was immediately needed. On-demand publishing is a prime example of the JIT inventory method, and it has become popular with independent publishers and self-publishing businesses. Master manuscripts of books are kept on hand, but texts are only printed and assembled as needed when a retail sale is made.

Recent Comments